General

Dhaka WASA adopted Supervisory Control and Data Acquisition (SCADA) system for digitalized handy operation practice for decision making officers, pursuing unmanned operation with minimized handy manpower. This implementation is playing an important role of forming Smart WASA and achieving the “Vision 2041”. SCADA is a comprehensive control system that enables real-time monitoring, data acquisition and remote control of DTWs. For better SCADA management a team is assigned with their certain roles and responsibilities aligning with their designation. This document stands for a complete framework for Production DTW SCADA operation in Dhaka WASA from field personnel to top supervision.

SCADA Set-up Demonstration

The SCADA set up of Dhaka WASA consist of 2 types of monitoring units: Central SCADA unit (Secondary Unit) and Zonal SCADA Unit (Primary Unit). Personnel from top to field level will be assigned individually to work as a team. The total manpower of this set up should be enough for providing 24/7 services regarding SCADA operation and maintenance.

Central SCADA Unit

A central SCADA unit is established in the head quarter of Dhaka WASA. From this unit a complete picture of the whole Dhaka City can be visualized and monitored. But this unit will not have access to control any part of the network, only monitoring functions with regular report generation will be done as well as acknowledgement of any critical event from the monitoring screen. This unit will provide summary of operation (in real-time), trend, alarm, and event list to enable the personnel to overview the whole water production status. It is treated as secondary unit for operation and maintenance.

Zonal SCADA Unit

Dhaka WASA consists 10 MODS Zone office for field management. There is a dedicated small SCADA unit with separate space and equipment in each zone. From this primary SCADA unit, precise monitoring is done for individual zonal area. This unit has access to both monitoring and control as well as data acquisition. Regular reports with respect to the corresponding zone will be produced and decisions will be taken based on the generated reports and acquired data.

Treatment Plant SCADA Unit

Dhaka WASA has 4 water treatment plant to feed the surface water to local networks. In each plant there is independent SCADA system to run the treatment plant.

Overall SCADA Operation Framework

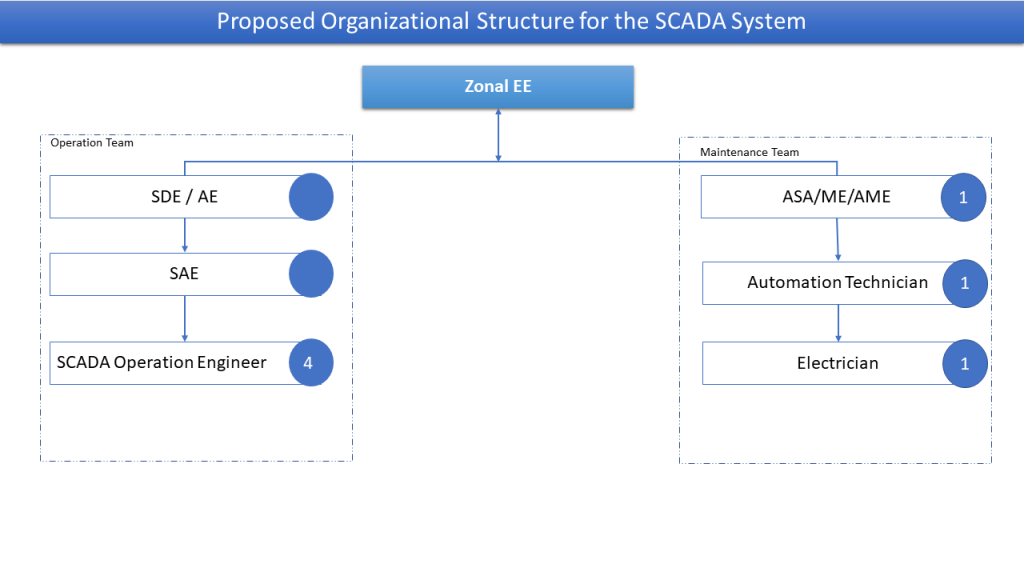

Proposed organizational structure for the SCADA

| Legend | Education Qualification | Responsibilities |

| ASA (Assistant System Analyst) | BSc. In Computer Science and Engineering or Equivalent Engineering (BSc.) Degree | Maintains and enhances programmable logic controllers (PLC) and supervisory control and data acquisition (SCADA) systems; troubleshoots, updates, modifies design and drawings pertaining to PLC/SCADA system. Performs preventive and corrective maintenance on all electrical, electronic and instrumentation equipment associated with the water supply system. |

| ME (Maintenance Engineer) | BSc. In Computer Science and Engineering or Equivalent Engineering (BSc.) Degree | |

| AME (Assistant Maintenance Engineer) | BSc. In Computer Science and Engineering or Equivalent Engineering (BSc.) Degree | |

| Automation Technician | Diploma in Electrical/Electronics/Computer Technology | Follow the instructions of ASA/ME/AME. Check the components of the DTW operation as well as SCADA equipment at each DTW. Acknowledge the problem and convey the observations to SCADA Operation Engineers. |

| Electrician | Related certificate must be needed | Follow the instructions of ASA/ME/AME. |

SCADA Operation Team

The SCADA Team consists of Top Supervision Team, Execution Team and Supporting Unit. Chief Engineer, 2 Superintending Engineers of MODS Circles, 10 Executive Engineers assigned for 10 Zones, 2-3 Sub-divisional Engineers/Assistant Engineers from each zone, 4 SCADA Operation Engineers for each Zonal SCADA unit, 4 electricians assigned for DTW in each zone as a supporting staff for the operation team, 8 SCADA Operation Engineers in Central SCADA unit, Emergency supporting team with FM divisions, Generator Division, SOC Division and the SCADA maintenance team.

Roles and Responsibilities

Top Supervision

- Discuss the critical events, accidents, crisis and complex problem with zonal Executive Engineers assigned for concerned zone.

- Report to Top Management of Dhaka WASA and Ministry for overall condition of Water Supply of Dhaka WASA.

Execution Team

Executive Engineer

- Supervision of the Zonal SCADA activities.

- Allocation of manpower and resources

- Decision making regarding DTW Pump Operation.

- Acknowledge top management regarding unusual events.

- Communicate with FM divisions, Generator Division, SOC Division in emergency situation.

- Submission of supervisory report to Top supervisory personnel.

- Procuring required equipment/goods

Sub-Divisional Engineer/Assistant Engineer

- Supervise the daily report.

- Discuss with Executive Engineers regarding complaints lodged by SCADA operation Engineer and take necessary steps to resolve.

- Communicate with the Emergency support unit as per requirement.

- Report to Executive Engineer for any unusual event.

- Scheduling roster duties for SCADA Operation Engineers.

- Submission of daily and monthly report to Executive Engineer.

- Data analysis such as total production, cost of production.

SCADA Operation Engineer

- Control & Monitoring of VFD

- Water Production Monitoring

- Line pressure Monitoring

- Underground Water level Monitoring

- Energy Monitoring

- Report Generation

- Chlorination Monitoring

- Communication with handymen

- Report to SCADA maintenance team regarding monitoring observations as well as hardware/ software/communication problem.

Field Operation

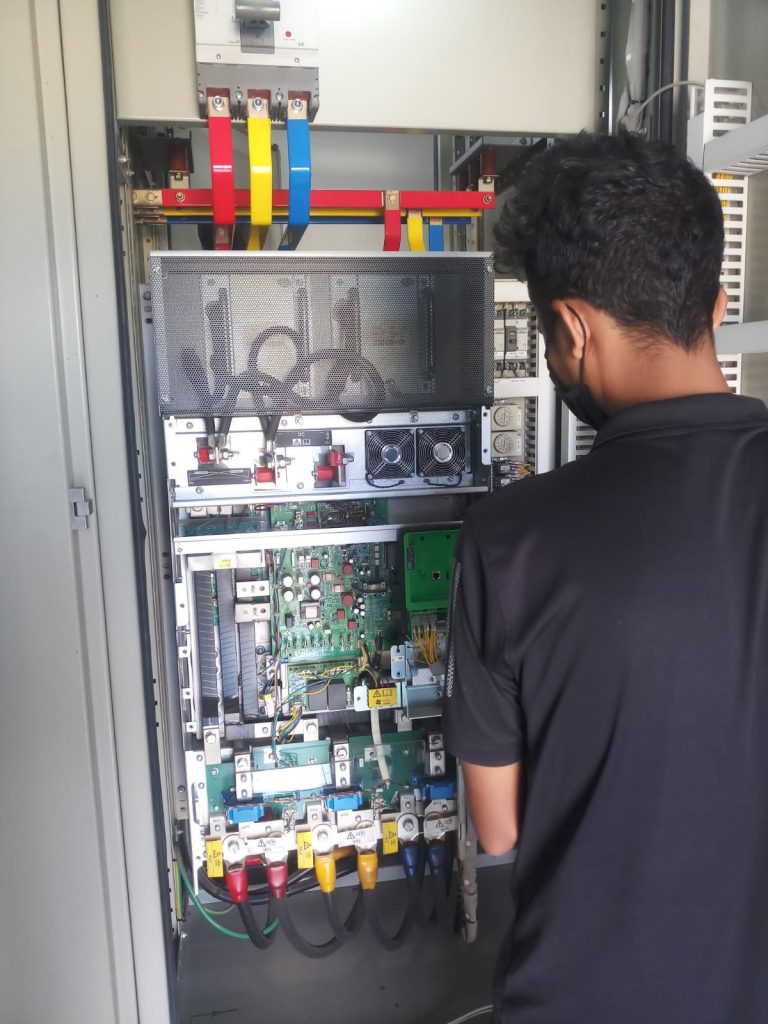

Maintenance Team

Maintains and enhances programmable logic controllers (PLC) and supervisory control and data acquisition (SCADA) systems; troubleshoots, updates, modifies design and drawings pertaining to PLC/SCADA system. Performs preventive and corrective maintenance on all electrical, electronic and instrumentation equipment associated with the water supply system.

- Performs corrective and preventive maintenance and repair work on the SCADA and PLC systems, as well as, a variety of electric, electronic and instrumentation equipment: electrical motors, transformers, electrical distribution systems, variable frequency drives, complex equipment control systems, and programmable logic controllers. Installs electrical appurtenances. Inspects and adjusts plant equipment as part of a comprehensive preventive maintenance program.

- Troubleshoots PLC and SCADA systems and equipment failures; analyzes and diagnoses problems; plans corrective action to plant and system maintenance problems. Replaces or rebuilds parts and equipment as needed.

- Manages the telemetry, PLC and SCADA systems; upgrades systems, drawings and software.

- Plans and performs projects for equipment, instrument, and system upgrades or replacements; conducts project research, conducts planning and design, working with engineering, vendor or contractor liaison; performs fabrication, testing, and installations.

- Maintains complete and accurate computerized maintenance management records of work performed; generates work orders and reports; maintains log; generates charts and plans.

- Provides on-the-job training in safe and efficient maintenance techniques and specialized skills for Maintenance Technicians. Ensures work methods comply with recognized City, state, and national standards.

- Performs preventive maintenance such as conducting inspections, cleaning, lubricating, checking tolerances, and exercising pumps, motors, compressors, instrumentation and metering equipment; also performs new installation reviews and inspections, quality control, and punch lists.

- Contacts other departments, vendors, and outside agencies to gather information regarding equipment acquisition, and support services as necessary

Transportation

- Transportation to move to deep tube wells for maintenance and troubleshooting purposes.

- One electric bike/appropriate two-wheeler to be provided to each handyman for monitoring and manual operation of deep tube-wells.

- One classic / non-sporty motor cycle to be provided to each SCADA team for quick troubleshooting of remote pump station.

Equipment and Tools

General Tools

1 Set for ASA/ME/AME and 1 set for automation technician and 2 Set for electrician

| No | Item | Unit | Q’ty | Remarks | |

| ASA/ME/AME | AT/Electrician | ||||

| 1 | Safety Belt | Set | 2 | ||

| 2 | Hammer 1/2 pound | EA | 1 | 2 | |

| 3 | Standard Tool Box | EA | 1 | 2 | |

| 4 | Cable Cutter | EA | 1 | 2 | |

| 5 | Screw Driver ‘+’ 4 inch | EA | 1 | 3 | |

| 6 | Screw Driver ‘-‘ 4 inch | EA | 1 | 3 | |

| 7 | Screw Driver ‘+’ 4 short tip | EA | 1 | 3 | |

| 8 | Screw Driver ‘-‘ 4 short tip | EA | 1 | 3 | |

| 9 | Wind mini screw driver for instrument, + | EA | 1 | 3 | |

| 10 | Wind mini screw driver for instrument, – | EA | 1 | 3 | |

| 11 | plier, 6-inch, combination | EA | 1 | 2 | |

| 12 | Long nose plier, 6 inches | EA | 1 | 2 | |

| 13 | Wire stripper | EA | 1 | 3 | |

| 14 | Cable crimping tool | EA | 1 | 2 | |

| 15 | Electric test pen | EA | 1 | 2 | |

| 16 | Multi-meter, DC mA measurable | Set | 1 | 2 | |

| 17 | Clamp on meter, up to 400A | Set | 1 | 2 | |

| 18 | Cable lug (100 pcs per pack) – Y Lug | Pack | 1 | 3 | |

| 19 | Cable lug (100 pcs per pack) – pin Lug | Pack | 1 | 3 | |

| 20 | Adjustable spanner – 4 inch | Set | 1 | 2 | |

| 21 | Adjustable spanner – 10 inch | Set | 1 | 2 | |

| 22 | Combination spanner (open and ring end) set – 12 pcs | Set | 1 | 2 | |

| 23 | L wrench hex key set | Set | 1 | 2 | |

| 24 | Portable air blower/dust sucker/vacuum cleaner | Set | 1 | 1 | |

Special Maintenance Tools and Equipment

Special Tools and Equipment are for special use and shall be kept by ASA/ME/AME

| No | Item | Unit | Q’ty | Remarks | ||

| ASA/ME/AME | AT/Electrician | |||||

| 1 | Loop calibrator, 4-20mA, Fluke 789 | Set | 1 | |||

| 2 | Hand pressure pump with gauge, Fluke 700PTPK2 + 700G27 | Set | 1 | |||

| 3 | USB to RS-485 Converter with 1.5 m cable | EA | 1 | |||

| 4 | USB to RS-232 Converter, 9 pin male with 1.5 m cable | EA | 1 | |||

| 5 | Megger Test, up to 1000V, Fluke 1507 | Set | 1 | |||

| 6 | Laptop Computer, for PLC program check at DTW | Set | 1 | |||

| 7 | Earth Tester | Set | 1 | |||

| 8 | LAN Cable, 3 meter long | EA | 5 | |||

| 9 | LAN Cable, CAT 6 | m | 300(= 1 roll) | |||

| 10 | LAN Connector, RJ45, 100pcs/pack | Pack | 1 | |||

| 11 | RJ45 crimping tool (LAN connector crimping tool) | EA | 1 | |||

| 12 | Necessary software with valid license for the maintenance of the system. | |||||

Support Unit

- Breakdown of pumps and disturbance of other machineries will be taken care by FM and Generator Division of Dhaka WASA.

- Problems regarding Chlorination will be taken care by SOC Division of Dhaka WASA.

- Problem with the connection will be taken care by network suppliers.

- Problems related to PLC/SCADA software and Touch HMI will be taken care by SCADA maintenance team.

- Problems related to PLC/SCADA software and Touch HMI will be taken care by SCADA maintenance team. If the maintenance team fail to solve then the contractor or the related expert will take care.